It was common for shops to have a central power source that drove all the tools through a system of belts, wheels and driveshafts. The power was routed around the work space by mechanical means. While the belts and shafts may be gone, many shops still use a mechanical system to move power around the shop. It's based on the energy stored in air that's under pressure, and the heart of the system is the air compressor.

You'll find air compressors used in a wide range of situations—from corner gas stations to major manufacturing plants. And, more and more, air compressors are finding their way into home workshops, basements and garages. Models sized to handle every job, from inflating pool toys to powering tools such as nail guns, sanders, drills, impact wrenches, staplers and spray guns are now available through local home centers, tool dealers and mail-order catalogs.

The big advantage of air power is that each tool doesn't need its own bulky motor. Instead, a single motor on the compressor converts the electrical energy into kinetic energy. This makes for light, compact, easy-to-handle tools that run quietly and have fewer parts that wear out.

Air compressor types

While there are compressors that use rotating impellers to generate air pressure, positive-displacement compressors are more common and include the models used by homeowners, woodworkers, mechanics and contractors. Here, air pressure is increased by reducing the size of the space that contains the air. Most of the compressors you'll run across do this job with a reciprocating piston.

Like a small internal combustion engine, a conventional piston compressor has a crankshaft, a connecting rod and piston, a cylinder and a valve head. The crankshaft is driven by either an electric motor or a gas engine. While there are small models that are comprised of just the pump and motor, most compressors have an air tank to hold a quantity of air within a preset pressure range. The compressed air in the tank drives the air tools, and the motor cycles on and off to automatically maintain pressure in the tank.

At the top of the cylinder, you'll find a valve head that holds the inlet and discharge valves. Both are simply thin metal flaps–one mounted underneath and one mounted on top of the valve plate. As the piston moves down, a vacuum is created above it. This allows outside air at atmospheric pressure to push open the inlet valve and fill the area above the piston. As the piston moves up, the air above it compresses, holds the inlet valve shut and pushes the discharge valve open. The air moves from the discharge port to the tank. With each stroke, more air enters the tank and the pressure rises.

Typical compressors come in 1- or 2-cylinder versions to suit the requirements of the tools they power. On the homeowner/contractor level, most of the 2-cylinder models operate just like single-cylinder versions, except that there are two strokes per revolution instead of one. Some commercial 2-cylinder compressors are 2-stage compressors–one piston pumps air into a second cylinder that further increases pressure.

Compressors use a pressure switch to stop the motor when tank pressure reaches a preset limit–about 125 psi for many single-stage models. Most of the time, though, you don't need that much pressure. Therefore, the air line will include a regulator that you set to match the pressure requirements of the tool you're using. A gauge before the regulator monitors tank pressure and a gauge after the regulator monitors air-line pressure. In addition, the tank has a safety valve that opens if the pressure switch malfunctions. The pressure switch may also incorporate an unloader valve that reduces tank pressure when the compressor is turned off.

Many articulated-piston compressors are oil lubricated. That is, they have an oil bath that splash-lubricates the bearings and cylinder walls as the crank rotates. The pistons have rings that help keep the compressed air on top of the piston and keep the lubricating oil away from the air. Rings, though, are not completely effective, so some oil will enter the compressed air in aerosol form.

Having oil in the air isn't necessarily a problem. Many air tools require oiling, and inline oilers are often added to increase a uniform supply to the tool. On the down side, these models require regular oil checks, periodic oil changes and they must be operated on a level surface. Most of all, there are some tools and situations that require oilfree air. Spray painting with oil in the airstream will cause finish problems. And many new woodworking air tools such as nailers and sanders are designed to be oilfree so there's no chance of fouling wood surfaces with oil. While solutions to the airborne oil problem include using an oil separator or filter in the air line, a better idea is to use an oilfree compressor that uses permanently lubricated bearings in place of the oil bath.

A variation on the automotive-type piston compressor is a model that uses a one-piece piston/connecting rod. Because there is no wrist pin, the piston leans from side to side as the eccentric journal on the shaft moves it up and down. A seal around the piston maintains contact with the cylinder walls and prevents air leakage.

Where air requirements are modest, a diaphragm compressor can be effective. In this design, a membrane between the piston and the compression chamber seals off the air and prevents leakage.

Compressor power

One of the factors used to designate compressor power is motor horsepower. However, this isn't the best indicator. You really need to know the amount of air the compressor can deliver at a specific pressure.

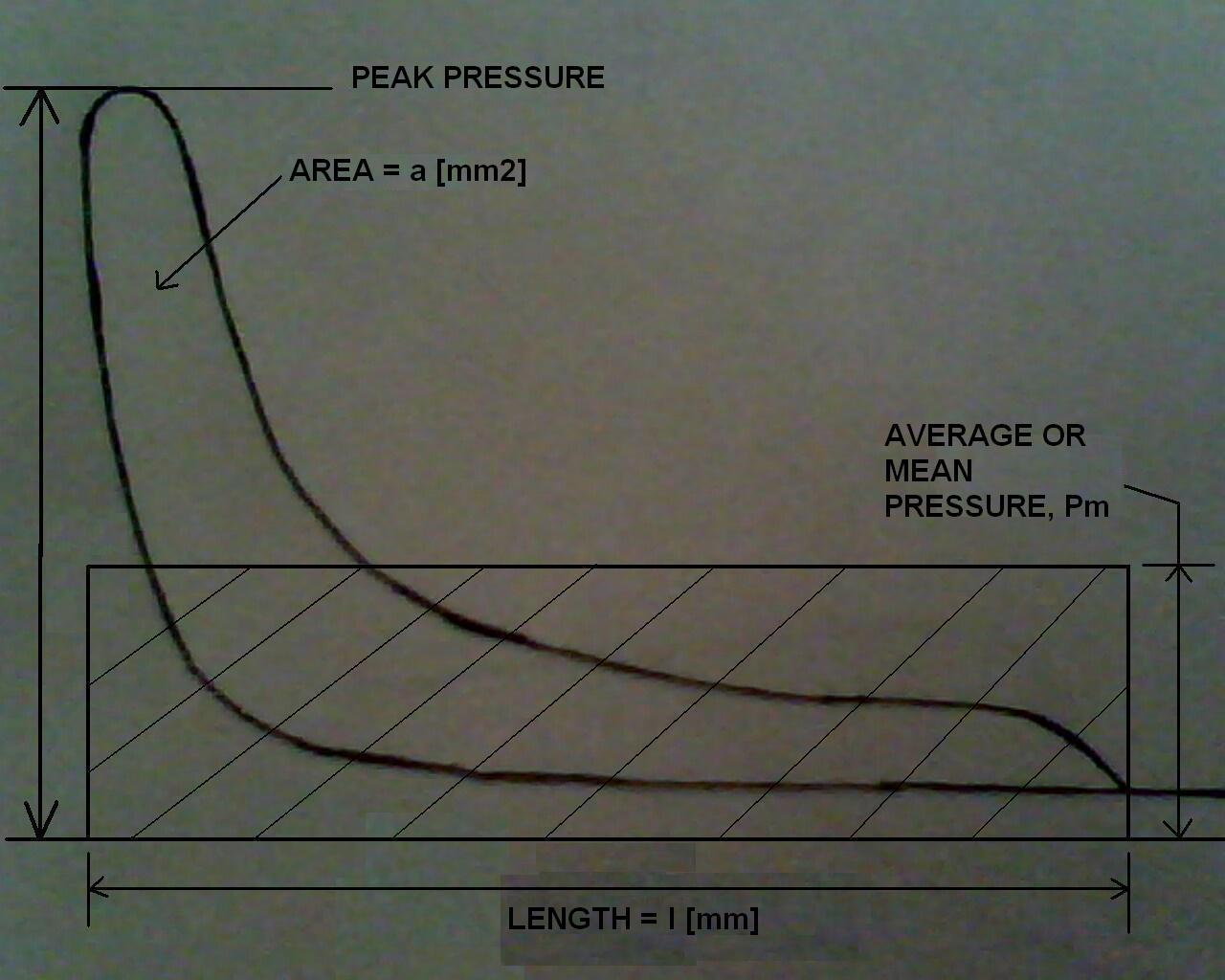

The rate at which a compressor can deliver a volume of air is noted in cubic feet per minute (cfm). Because atmospheric pressure plays a role in how fast air moves into the cylinder, cfm will vary with atmospheric pressure. It also varies with the temperature and humidity of the air. To set an even playing field, makers calculate standard cubic feet per minute (scfm) as cfm at sea level with 68 degrees F air at 36% relative humidity. Scfm ratings are given at a specific pressure–3.0 scfm at 90 psi, for example. If you reduce pressure, scfm goes up, and vice versa.

You also may run across a rating called displacement cfm. This figure is the product of cylinder displacement and motor rpm. In comparison with scfm, it provides an index of compressor pump efficiency.

The cfm and psi ratings are important because they indicate the tools that a particular compressor can drive. When choosing a compressor, make sure it can supply the amount of air and the pressure that your tools need.